Ballistics testing is not created equal

I was reviewing some of our ballistics test reports from National Institute of Justice (NIJ) certified labs recently. I remembered some challenges we have had during various R&D testing and wanted to share some of my thoughts regarding variables in ballistics testing that customers need to understand.

Bullets, or projectiles are strange, finicky things. You can pass dozens of tests on a plate and then get something unexpected. It's important to note a few things about ballistics testing and to be able to tie them together into an ability to draw reasonable conclusions.

Just because our Model 1023 shows the plate resisting six shots of .30 M2AP, it does not mean that the test can be repeated every time. Repeated testing can show a reliability in the materials layering that comprises the armor system. But, there are variabilities in the manufacturing and assembly processes that can have an impact on performance. These variables are almost too many to mention: press methodology, oven temperatures, adhesives quality, shot spacing, the yaw or tumbling of a projectile as it enters the armor, etc. All of these things are important to consider. The most important thing you can look for as a customer in testing is the consistency of good results. Is the armor offering appropriate ballistic resistance to the specified threat(s) on a consistent basis?

Another point I want to make is that NIJ-tested armor is not the same thing as NIJ-certified armor. There is a significant difference between the two.

Many manufacturers (and resellers) will test their armor with one of the NIJ certified ballistics labs. These tests are normally ballistic "V0" tests, where a certain RF1, RF2, or RF3 threat is tested against the armor at as close to 0° as possible (straight on shots). A ballistics report is then generated and shared with customers as part of "proof" that the armor can perform as advertised. There are factors in these V0 tests that can impact the "value" of ballistics results.

What are some of these factors?

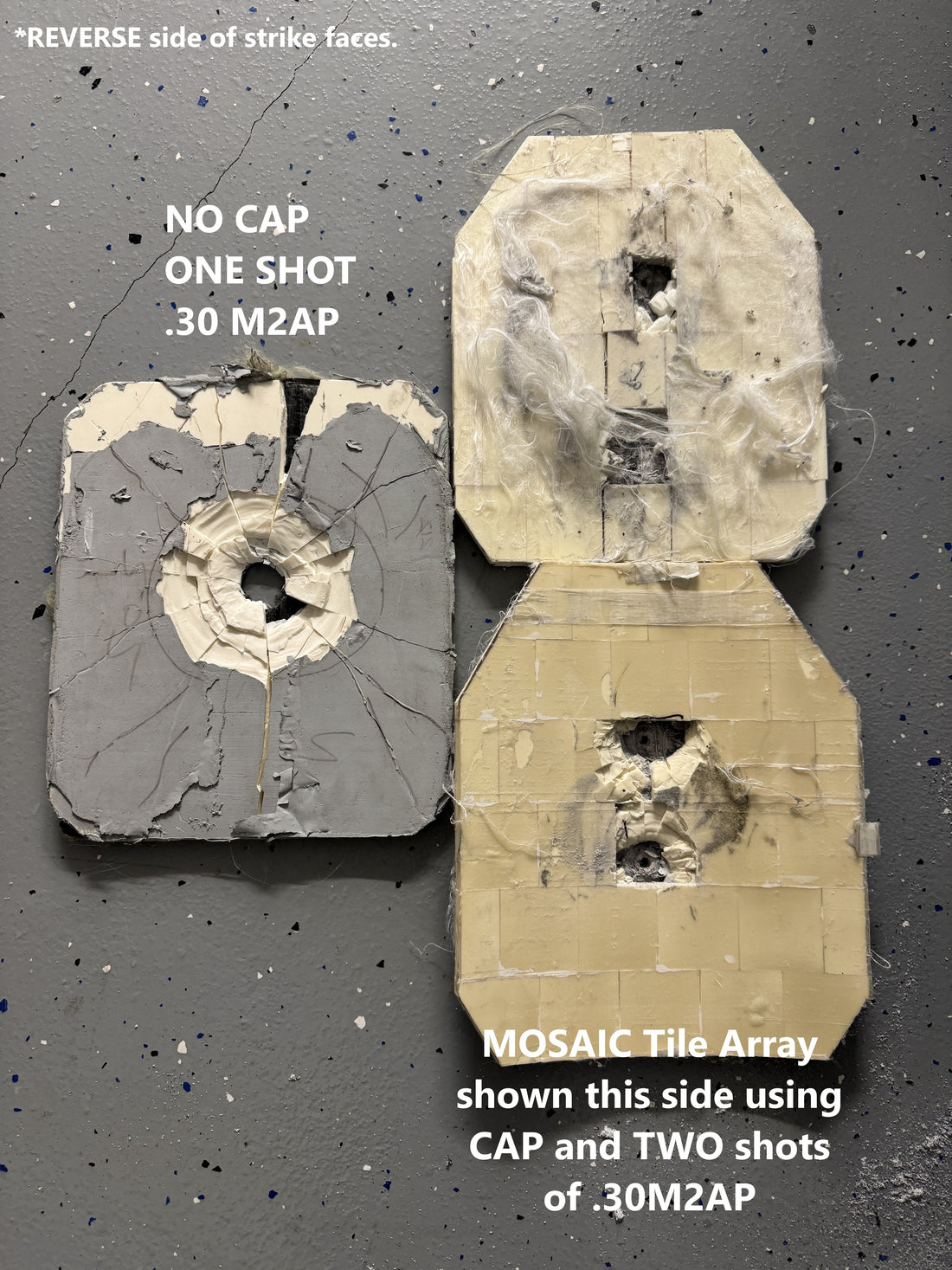

The placement of these shots (especially with RF3, .30 M2AP) have an incredible impact on the viability of the test. Customers should know that the crown of the armor plate is its most vulnerable location. Think of the crown as the highest point on the armor. If you lay the plate flat on a table (wear face down), a single-plate crown runs along the vertical centerline of the plate. A multi-curve plate crown is a point at which all of the plate angles intersect. Unless at least one shot is placed on the crown during testing, the armor's true resistance is not tested. Customers should look for shot locations on the lab reports ("CR" or "CROWN"). Shots placed outside of the crown are fair hits, but resisting in many of those areas is easier than on crown shots.

Shots in ceramic armor plate locations outside of the crown are really not "V0" shots and do contact the plate at an angle (since the plate has some designed curvature). This angle of attack increases resistance due to additional material interacting with the projectile.

Sometimes, you will also see a manufacturer's field testing which shows a shot in the lower left or right corner. Other shots may be shown on the other corners with no crown shots. This is a warning sign... and customers should understand that these are not the armor's weakest points.

Many of these basic, V0 tests will not include drop testing or submersion testing. We normally do both unless the layup has had that type of testing done previously. The submersion testing is less important to me (still important) since most modern day adhesives are waterproof. The real value in a submersion test is to test adhesive strength while wet and flex strength during water induced temperature changes.

Drop testing is referred to as mechanical testing. Monolithic armor (single piece of ceramic ballistic tile) is far more susceptible to cracking from dropping than armor built with ceramic tile arrays. The pre-engineered seam lines between the smaller pieces of tile in the array makes the design better able to handle the two drops required of NIJ 0101.07 ballistic standards. This is especially true when the array is built with adhesives between the ballistic tile pieces in the array pattern.

NIJ lab ballistic test reports without drop testing are less relevant in measuring an armor's resistance after being subjected to drops that could occur over the course of normal handling. The NIJ 0101.07 2x drop at 48" with ten pounds of clay is designed to represent the normal physical stressors that can present themselves during the course of an armor's life. This test should never be excluded from testing (unless the materials stack has already been drop tested and documented).

NIJ lab V0 ballistics reports without drop testing and submersion and a lack of crown shots is (to me) almost useless in representing true performance.

NIJ 0101.07 certified armor is a whole different story. NIJ certified armor has to undergo initial type testing (ITT). The ITT process requires label testing, temperature conditioning, submersion, mechanical testing, Perforation Backface Deformation Testing and Ballistic Limit Testing.

When you purchase NIJ 0101.07 certified armor, you are acquiring armor that meets the latest, most stringent requirements in NIJ history. NIJ 0101.07 armor endures temperature conditioning (11 day temperature cycling) from 5°F - 194°F. You can reference the latest ASTM standard for hard armor conditioning for detailed information.

Should you request ballistics test reports for armor models that are NIJ certified? NIJ armor is entered into a Follow-Up Inspection and Testing (FIT) program that randomly samples individual plates from a manufacturer's supply. These samples must pass V0 testing at NIJ certified labs without any complete penetrations. The manufacturer's ballistic test reports can provide at least two important pieces of data (regarding certified armor):

- The test reports (issued to the manufacturer from the lab) will show you the amount of backface deformation (BFD) present in the testing (in mm).

- The test reports will show you how many shots the manufacturer's armor undergoes during its FIT test.

Regarding #2: The armor manufacturer must apply to the NIJ for model certification. Part of this certification includes an application where 1, 2, 3, or 6 shots (RF3) are selected as part of the initial type testing. The initial selection of shots for the initial type testing also matches the number of shots that must be resisted during random FIT sample tests. If you are able to view the manufacturer's ballistic tests generated during FIT testing, you will be able to see how many shots the plate resists as part of its initial type tests. This is important because a "2-shot" plate enduring the rigors of initial type testing had to have the BFD measured on all shots. This total BFD data was part of the overall certification, meaning that a 2-shot plate could be stronger than a 1-shot plate, etc. This could also mean simply that the manufacturer wanted to take "less" risk and engage 1-shot testing as part of risk mitigation of bringing a new armor to market.

Regardless of the number of shots taken during the certification process, all passing armor that is listed on the Compliant Products List (CPL) will NOT have the number of shots listed beside the armor or revealed.

There are many other things that impact what's on a lab's ballistic report. The temperature of the clay also has a major impact on BFD. If a clay block is 5°F hotter than another, there may be a 5mm BFD increase. I've seen many cases where the temperature had a significant impact on back face performance.

The most important aspect of lab reports to watch out for when reviewing a manufacturer's "passing" armor report is most certainly shot location. If you're not testing the crown, you're not testing the plate.