Gilliam Technical Services, Inc.

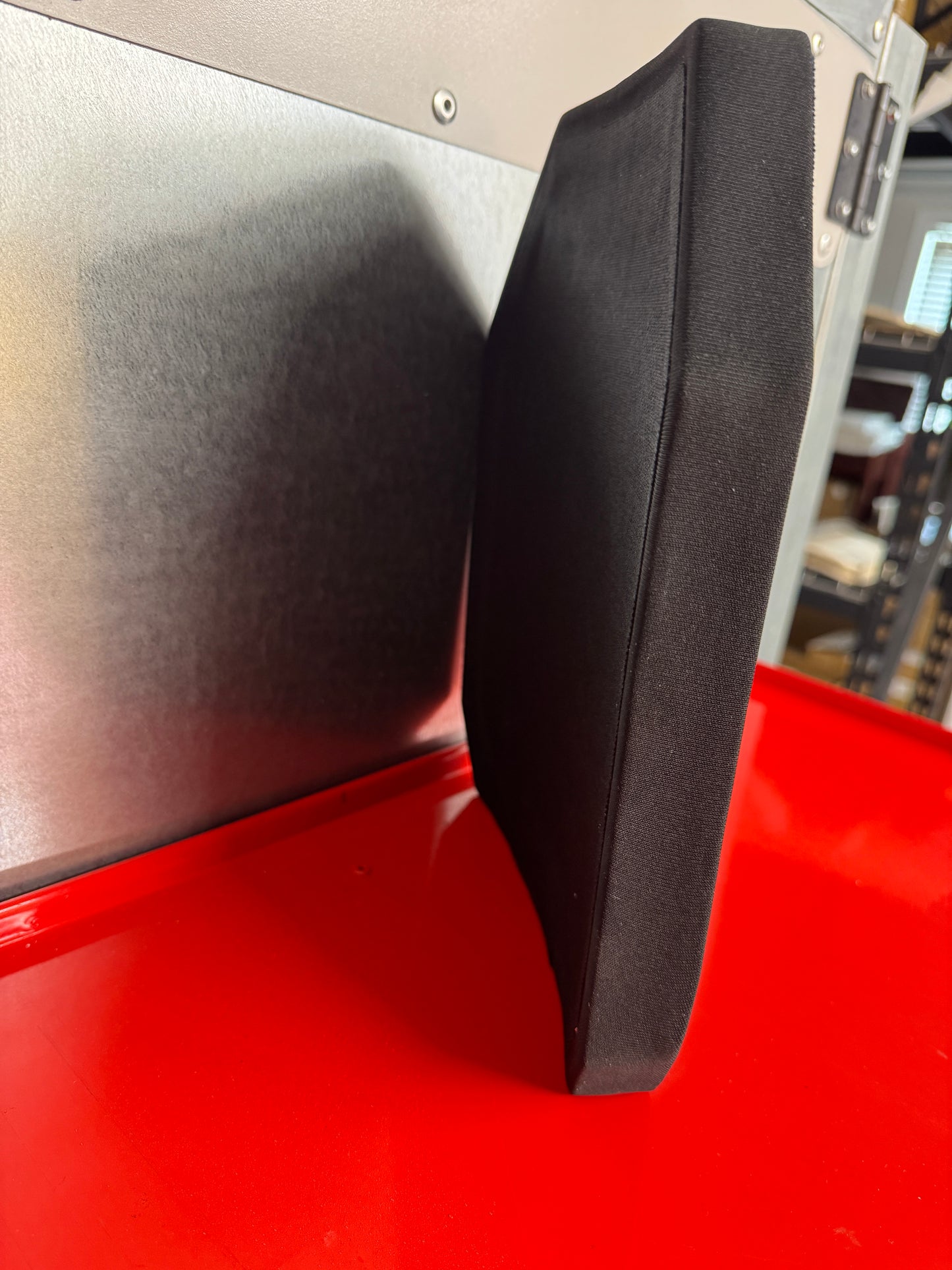

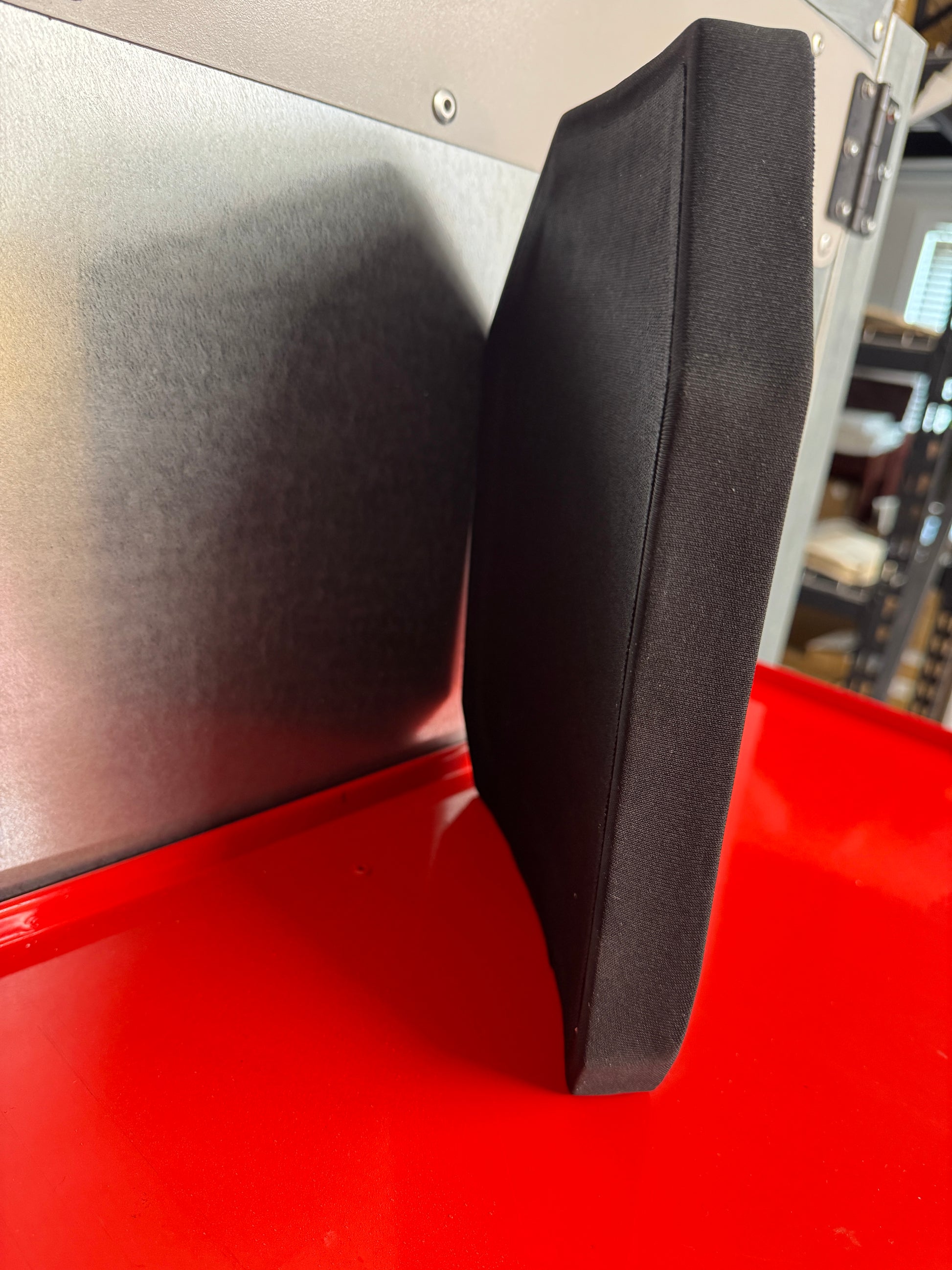

Model 1969: Max Power RF3 Low Spall Alumina Ceramic Armor Plate

Model 1969: Max Power RF3 Low Spall Alumina Ceramic Armor Plate

Couldn't load pickup availability

Overbuilt RF3 protection with ceramic fragmentation control. The Model 1969 delivers maximum armor-piercing protection with built-in redundancies and GTS ShardLock™ technology that eliminates ceramic fragmentation, providing clean, reliable performance in the most demanding scenarios.

Key Features:

- Overbuilt with redundancies - Engineered with built-in backup systems for maximum reliability and protection

- RF3 standalone protection - Tested to resist multiple rounds of .30-06 M2 AP armor-piercing ammunition

- GTS ShardLock™ fragmentation control - Ceramic fragmentation control on the strike face eliminates spall concerns

- Clean, no-lines strike face - Professional appearance with seamless fragmentation control integration

- 99%+ pure alumina mosaic ceramic - Superior ceramic tile array provides excellent multi-hit performance

- Multi-hit capable - Tested against multiple rounds of .30 M2AP plus other threats

- Made in the USA - Manufactured with proprietary ARMORFILM™ adhesives and high-quality materials

Technical Specifications:

| Model | 1969 |

| Protection Level | RF3 (Level IV) standalone |

| Size | 10" x 12" (multiple cuts available) |

| Cut Options | Shooter's Cut or SAPI Cut |

| Weight per plate | Shooter's Cut: 8 pounds / SAPI Cut: 8.2 pounds |

| Thickness | 1.1" |

| Ceramic Material | 99%+ pure alumina mosaic |

| Ceramic Configuration | Mosaic tile array |

| Spall Control | GTS ShardLock™ (full fragmentation control) |

| Backing Material | UHMWPE (Ultra-High-Molecular-Weight Polyethylene) |

| Curve Type | Single-curve |

| Edge Protection | 100% USA hard, high-temp rash edge |

| Adhesive | Proprietary ARMORFILM™ (Made in USA) |

| Outer Material | 1000 denier water-resistant nylon |

| NIJ Standard | 0101.07 RF3 / 0123.00 RF3 |

| Manufacturing | Made in the USA |

Ballistic Performance & Design:

The Model 1969 represents an overbuilt approach to ceramic armor design with built-in redundancies for maximum reliability. This plate is tested to resist multiple rounds of .30-06 M2 AP armor-piercing ammunition at 2880 feet per second, plus M80A1 and all RF1/RF2 threats including M193, M855, 7.62 x 51 MSC, 7.62 x 51mm M80, and M855A1. The RF3 protection level provides confidence in high-threat environments where armor-piercing ammunition may be encountered.

Multi-hit capabilities depend on many factors and may not be exactly repeatable between tests. GTS encourages you to look for consistency in performance between ballistics tests. The Model 1969 has demonstrated reliable multi-hit performance in testing, with the mosaic ceramic configuration helping to contain damage within smaller zones while maintaining protection across the rest of the plate.

Test reports for Model 9042 are also applicable for Model 1969. Reviews for Models 6906 and 9042 are relevant for Model 1969 performance characteristics. View our ballistics test reports.

GTS ShardLock™ Fragmentation Control:

The Model 1969 features GTS ShardLock™ technology, which provides full ceramic fragmentation control on the strike face. This advanced system eliminates the ceramic spall concerns that can occur with standard ceramic armor plates. When a projectile impacts the ceramic strike face, ShardLock™ contains the ceramic fragments, preventing them from becoming secondary projectiles that could pose risks in close-quarters environments.

The clean, "no lines" look on the strike face demonstrates the seamless integration of the fragmentation control system. Unlike some spall-control solutions that add visible layers or coatings, ShardLock™ is integrated into the plate construction for a professional appearance and reliable performance. This feature is particularly important for law enforcement and security professionals who may be operating in environments where ceramic fragmentation could affect nearby personnel or civilians.

Note that edge shots may generate some ceramic fragmentation.

Superior Materials & Construction:

The Model 1969 uses 99%+ pure alumina ceramic in a mosaic tile array configuration. This superior ceramic purity provides excellent hardness and fracture resistance. The mosaic pattern allows the armor to contain damage from multiple impacts within smaller zones, maintaining protection across the rest of the plate surface. This is the best performing ceramic armor configuration for multi-hit scenarios.

Better than competitor plates: GTS uses a crack arrestor, Ultra-High-Molecular-Weight-Polyethylene (UHMWPE) backers (no glass) and a 99%+ alumina ceramic tile array. The competition does not. The 100% USA hard, high-temp rash edge protects the ceramic edge during normal use, ensuring long-term durability even with daily handling.

All components are bonded using proprietary ARMORFILM™ adhesives that are 100% sourced and manufactured in the USA. The controlled pressure manufacturing process ensures consistent bonding and performance across every plate. The 1.1-inch thickness fits most carrier pockets designed for RF3 plates.

Overbuilt Design Philosophy:

The Model 1969 is described as "overbuilt" because it incorporates built-in redundancies and extra engineering margins beyond the minimum requirements to pass RF3 testing. This approach provides additional confidence in real-world scenarios where armor may be subjected to rough handling, environmental stress, or multiple impacts. The redundant design elements work together to maintain protection even under challenging conditions.

The single-curve design provides a balance between comfort and ease of manufacturing, making it compatible with most standard plate carriers. The 1000 denier water-resistant nylon cover protects the plate during daily use and provides a durable outer surface. Available in both Shooter's Cut and SAPI Cut configurations to fit various carrier systems and user preferences.

Specifications Table:

Applications & Use Cases:

The Model 1969 is ideal for law enforcement officers, military personnel, security professionals, and civilians who require maximum rifle threat protection with full ceramic fragmentation control. The overbuilt design makes it particularly well-suited for high-risk environments where armor reliability is critical and the GTS ShardLock™ technology provides additional confidence in close-quarters scenarios.

The RF3 protection level makes it suitable for high-threat environments where armor-piercing ammunition may be encountered. Available in both Shooter's Cut (for maximum weapon handling mobility) and SAPI Cut (for broader compatibility with carriers) configurations. The standalone design means no soft armor backing is required, simplifying your armor system while maintaining full RF3 protection.

*Please remember that multi-hit abilities depend on many factors and may not be exactly repeatable between tests. We encourage you to look for consistency in performance between ballistics tests.

U.S. Law prohibits persons convicted of certain violent state and/or federal felonies from purchasing body armor. You are responsible for knowledge of and compliance with federal, state and local laws regarding body armor.

All sales are in compliance with and customer acknowledgement of our Return Policy and LEGAL NOTICE here. Please wear your armor in compliance with the ballistic label included on your product. DO NOT test your armor by intentionally wearing it during ballistic testing.

Shipping

Shipping

This item is shipped using UPS Ground, USPS Priority or Ground Advantage.

Once placed with the carrier, we are not able to see any more details than is available referencing the tracking number provided.

We cannot control the speed of the carrier's delivery once the item(s) is shipped.

Terms and Conditions

Terms and Conditions

This sale is in accordance with our Legal Policy , Shipping Policy and Terms of Service.